Company creates robotic year-round greenhouses

Published 4:44 pm Friday, November 8, 2024

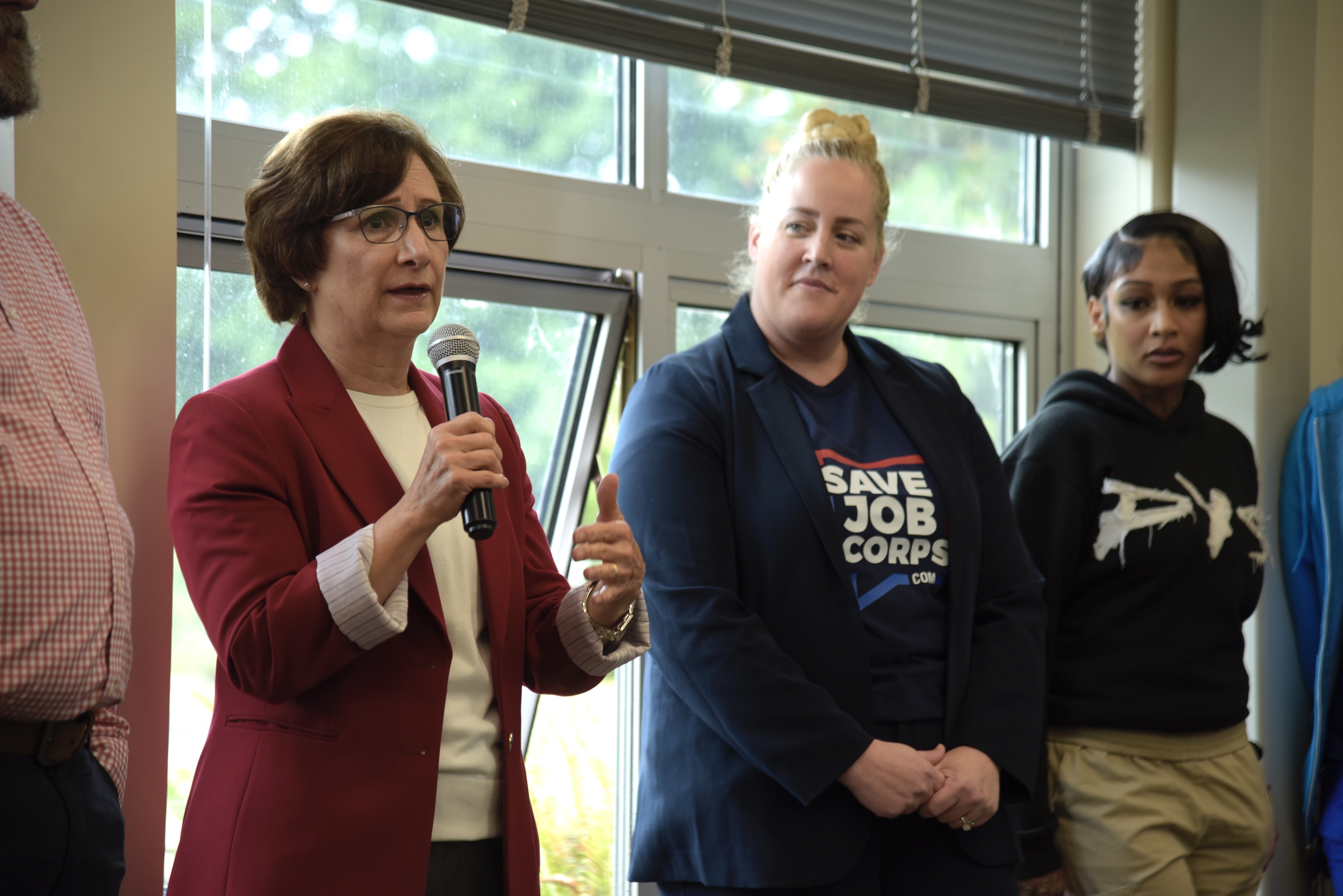

- Canopii founder and CTO Justin Gravett, Lewis Drapete, electromechanical engineer, Sam Pepperwood, senior mechanical engineer, and David Ashton, founder and CEO, stand in their prototype automated greenhouse.

HUBBARD — About a decade ago, David Ashton and Justin Gravett were college roommates studying engineering at California Polytechnic State University.

Now the friends are trying to change the future of agriculture. Their company, Canopii, is creating automated greenhouses to vertically grow and harvest leafy greens and herbs.

“People won’t have to go into the greenhouse except for once every two weeks,” said Ashton, the company’s CEO.

The futuristic concept, which combines cutting-edge technology with sustainable farming practices, would have seemed like wishful thinking from “The Jetsons” television show a few decades ago.

But many industries, including agriculture, are increasingly relying on robotics and other technologies to boost production and profits.

Three years after forming, Canopii has $1 million in venture funding and $1.3 million in grants.

“We’re the dog that caught the car,” Ashton chuckled, as he stood in a prototype greenhouse three stories tall, the smell of basil and potting soil mixing in the air.

A carousel lifted vertical rows dotted with green starts nearly up to the translucent ceiling before lowering them toward the floor, ever repeating its slow circular motion.

A robotic greenhouse

Seasons change. Growing conditions inside Canopii greenhouses won’t, for the most part.

The carousel provides all plants inside with natural sunshine, though LED lights near the bottom provide a supplemental boost during winter.

The design should save energy costs compared to other indoor growing options. The company is also shooting for organic certification, Ashton said.

Canopii uses a closed-loop watering system that should reduce use by 90% compared to conventional agriculture.

Plant cups are washed and reused in the automated system, as well, minimizing purchases and waste.

“We removed one-time use plastics,” Ashton said.

The carousel also simplifies the mechanics of the greenhouse by essentially bringing plants to the robots.

Canopii greenhouses will include seeding, cutting and cleaning stations and a conveyor belt to take produce to cold storage.

Though the greenhouses are 30 feet tall, their footprint is the size of a basketball court.

Canopii’s target market is small- to medium-sized growers in the Pacific Northwest who can diversify year-round with the greenhouses by continuously growing and harvesting lettuce, spinach, basil and other crops — perhaps even peppers, berries and tree starts someday. Those crops are high value but need to be refrigerated and degrade in quality quickly.

Canopii greenhouses would ensure freshness while eliminating transportation and labor costs, Ashton said.

The structures are also sealed, so contamination from animals or handling, a major concern with leafy greens, is greatly reduced.

The greenhouses’ small footprint makes them ideal for parking lots or even some urban environments, and they’re designed with city zoning codes in mind.

Ashton said he’s been in contact with restaurateurs, grocery chains and schools about Canopii greenhouses providing a hyperlocal source of produce as close to consumers as possible.

Leafy greens on store shelves or in restaurant dishes could have been picked on-site hours earlier.

“Instead of buying from wholesalers, they could buy the farm and then just make profit. … This is like buying a house and building equity,” Ashton said.

“The fact this is so autonomous is appealing,” he added.

The greenhouses will cost about $1 million to purchase, along with an annual maintenance fee of about $30,000.

During twice-a-month visits, Canopii personnel would provide software updates, monitor crops, change filters and perform other maintenance.

“The degree of automation on this — it’s more affordable than anything else on the market by far,” Ashton said.

That lowers barriers to entry so farmers and organizations can gradually scale up with Canopii.

Supporter bets on success

Supporters such as Hubbard company GK Machine Inc. are betting on Canopii’s success.

The manufacturing firm makes parts and will construct the greenhouses. It also rents land and office space to Canopii.

Leaders at GK Machine believed in Canopii’s vision, and they’ll get plenty of work if the company succeeds.

They stressed that the greenhouses are U.S. made and sourced.

“We pride ourselves on using American steel. We want to support those industries before going overseas,” said Connie Lindsay, GK Machine director of sales and marketing.

GK Machine already sold and manufactured greenhouses, so Canopii’s design is similar except for the technological components inside.

Besides purchasing, manufacturing and construction expertise, GK Machine’s involvement brings a sort of instant credibility to Canopii, Ashton said.

GK Machine started in 1974 after owner Gary Grossen graduated from nearby Woodburn High School and started repairing farm equipment.

Now the company has nearly 200 employees including engineers and electricians, and Grossen plans to increase sales and staff.

Canopii’s prototype at GK Machine serves as a showcase for potential customers. “They’re just blown away,” Lindsay said.

While GK Machine has worked with startups before — Lindsay said she can’t talk about the “coolest” projects due to nondisclosure agreements — this is the first business the company has incubated on its 192-acre property.

Grossen knows he’s taking a gamble. “I’ve done that all my life,” he said.

“He’s willing to take a risk, especially if he sees an opportunity for automation and robotics to be integrated into agriculture. It’s kind of that frontier,” Lindsay said.