Seaside considers wastewater investment

Published 4:33 pm Wednesday, June 30, 2021

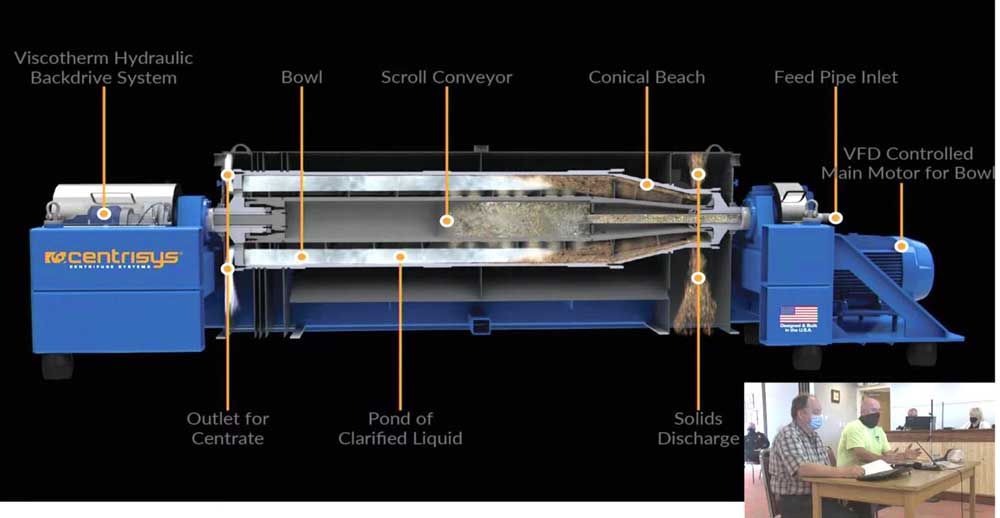

- The City Council has discussed a sludge press and dryer unit designed by Centrisys.

SEASIDE — A new, $3.1 million press and drying system for the city’s wastewater treatment plant could increase capacity and lower costs.

Trending

The proposal was presented by Dale McDowell, the city’s public works director, and Tony Biamont, the treatment plant operator, at Monday’s City Council meeting.

Public works is seeking a better solution for the treatment plant as the drying and processing plant has seen better days, McDowell said.

The proposal he and Biamont presented could also provide U.S. Environmental Protection Agency Class A biosolid product suitable for agriculture purposes, which the city could turn a profit from.

Trending

Class A designates dewatered and heated sewage sludge that meets the federal agency’s guidelines for land application with no restrictions.

“This stuff is super absorbent of water,” Biamont said. “It pulls the water out of the ground. It’s far better than we could have ever imagined.”

The city’s wastewater drying system faces frequent downtime, McDowell said. “The used dryer has worked great for a few years. But we’re spending more time working on it, repairing it,” he said. “Parts are no longer available and staff are struggling to keep it clean. Now it’s time to look beyond this dryer.”

The city’s Fenton Fenix dryer, purchased in 2012 when it was already 10 years old, could be sold for $50,000 to $60,000, because it’s very sought after, McDowell added. The dryer may have some parts that are of value to someone that has the same unit.

The system processes 365,000 gallons a week. The proposed Centrisys system does that in three days, Biamont said.

According to product specifications, the unit works using centrifugal force to push heavier particles through the liquid collected on the inner wall of the bowl. The high-speed rotation of the bowl separates the solid and liquid materials to create biosolids.

Low-temperature drying reduces potential injuries and fire hazards, McDowell said. Parts are readily available from the company, based in Kenosha, Wisconsin.

The $3.1 million cost includes the dryer and centrifuge, Biamont said, with an additional $300,000 to $400,000 for construction.

After processing, the sludge can be sold for agricultural purposes. Seaside’s biosolids are so rich in nutrients that it would not require watering or nitrogen pellets to produce higher yields.

While the city doesn’t charge for biosolids now, the sewer plant has the potential to create a revenue stream, Biamont said, with customers throughout the region bringing their own sewage to Seaside for processing at a price lower than alternatives for disposal.

The city has not evaluated how the equipment might be paid for, City Manager Mark Winstanley said. Monday’s presentation was a prelude to possible action later this year.

“One of the reasons why it’s a little bit fluid is because we’re in a period where our ability to access funds that we normally would not be able to get is a little bit greater than it has been in the past,” Winstanley said. “Certainly, one of the things that we’re looking at is the federal government’s interest in an infrastructure bill and whether that is a source of funding we would be able to use. I hate to get in front of that bill, but I’d like to be able to see what that looks like.”

“Clearly, from my opinion, this is a no-brainer,” Mayor Jay Barber said. “It’s got to be done. And we want our workers to remain safe on the job and we want to furnish a good product for the agricultural community. … I think it’s got to be done.”